Image 1 of 4

Image 1 of 4

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

Image 4 of 4

Image 4 of 4

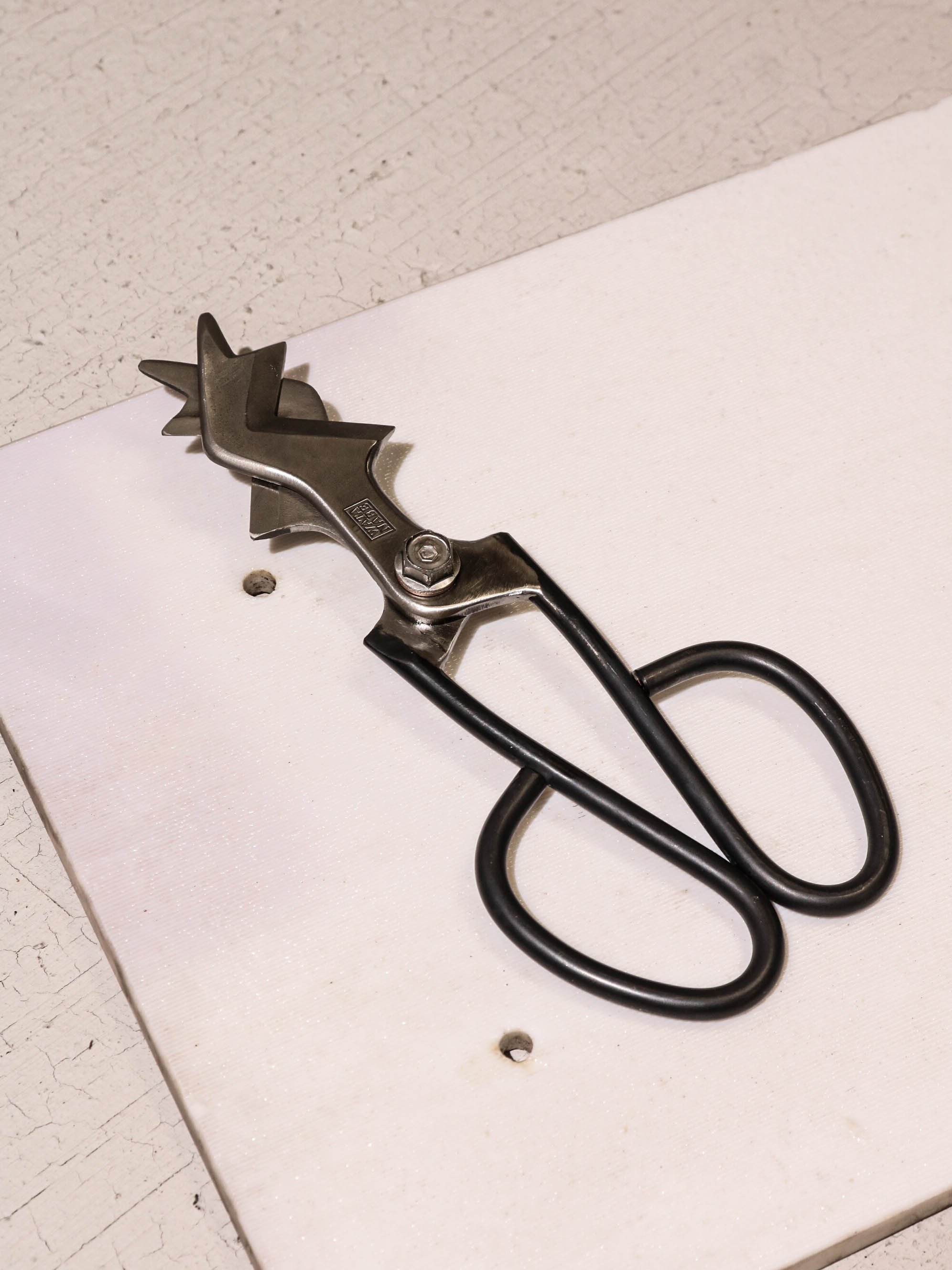

German Medium Shears

Back in 1871, hermann putsch started a company in the food processing industry with his beet slicing machine. It was several deacdes of innovation, building of mold blowing, and hot glass press forming equipment the 40’s, the establishment of Putsch groups in Spain in 1956, Italy in 1957, and the US in 1975 - that lead the company to design and build some of the glass industry’s most beloved tools and equipment. Putsch cutting tools, jacks and tweezers are very common in the European glass scene, and coveted in the states.

Putsch medium shears were very popular on the island of Murano - whether they were made in Germany, Italy or Spain, they became quite common on Italian benches since hitting the market in the 50’s. It was this tool that Gaio Arturo made his groundbreaking iteration of which lead to a new generation of ergonomic glassblowing tools that could be wielded by hands of all sizes. Jeff Lindsay later took a pair of broken Gaios (famously brittle) and re designed them once again for the modern age - adding key innovations like a form fitting pipe grabber, thinner profile, ergonomic handles, and the use of indestructible D2 tool steel. Jeff Lindsay kicked off a real movement in the states and beyond which redefined not only the look, but also the function of glass blowing cutting tools. He taught us what was possible. Maruko, NRD, Jim Moore, myself, and others have all taken careful notes from Jeff and have taken his blueprints into our own shops for further investigation.

My offering is a sort of alternate universe version of this tool. It’s an interpretation of this same historic tool, but one that looks more like the original while incorporating modern touches like D2 and ergonomic handle geometry. Jeff Lindsay started off as a bike builder - which shows in his beautiful TIG brazed handle connections…… I’m unfortunately not a bike builder and thus have resorted to more familiar stainless welded connections. While this is maybe a bit less aesthetically impressive than a tight bare bronze TIG weld, it does offer a strong bond similar in style and technique to what you see in CD, Putsch, Novotny, or Gaio Arturo cutting tools - a tired and true transition between steels with a bit of personality.

My shears feature a thick, hand carved, 3/16” vacuum hardened D2 stock with a Rockwell C of about 60, triple tempered, ergonomic handle spacing, old French style handles (later appropriated by early Putsch and Fennek), welded handle connection and a proprietary fulcrum which features a Stainless bolt and stainless split lock washer, stainless nylock nut and two Oilite oil impregnated bronze thrust bearings - all for easily customizable tension.

These high quality and highly functional tools are hand made one at a time per order in Pawtucket, Rhode Island. Each tool shows clean and visible signs of being made by hand and each is a unique object.

Tools are made per order and are selling fast, please allow some lead time for tools to be made and shipped.

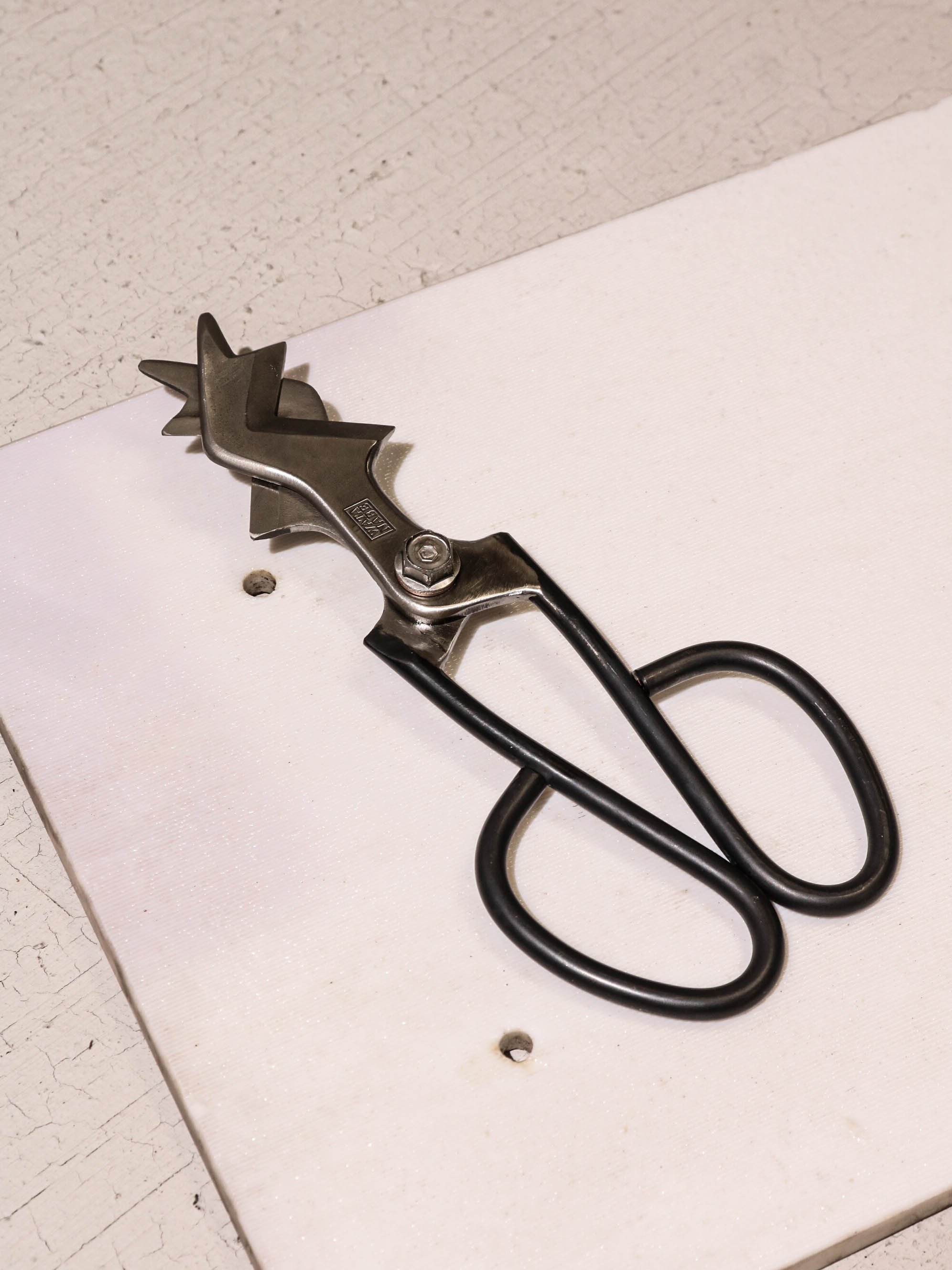

Back in 1871, hermann putsch started a company in the food processing industry with his beet slicing machine. It was several deacdes of innovation, building of mold blowing, and hot glass press forming equipment the 40’s, the establishment of Putsch groups in Spain in 1956, Italy in 1957, and the US in 1975 - that lead the company to design and build some of the glass industry’s most beloved tools and equipment. Putsch cutting tools, jacks and tweezers are very common in the European glass scene, and coveted in the states.

Putsch medium shears were very popular on the island of Murano - whether they were made in Germany, Italy or Spain, they became quite common on Italian benches since hitting the market in the 50’s. It was this tool that Gaio Arturo made his groundbreaking iteration of which lead to a new generation of ergonomic glassblowing tools that could be wielded by hands of all sizes. Jeff Lindsay later took a pair of broken Gaios (famously brittle) and re designed them once again for the modern age - adding key innovations like a form fitting pipe grabber, thinner profile, ergonomic handles, and the use of indestructible D2 tool steel. Jeff Lindsay kicked off a real movement in the states and beyond which redefined not only the look, but also the function of glass blowing cutting tools. He taught us what was possible. Maruko, NRD, Jim Moore, myself, and others have all taken careful notes from Jeff and have taken his blueprints into our own shops for further investigation.

My offering is a sort of alternate universe version of this tool. It’s an interpretation of this same historic tool, but one that looks more like the original while incorporating modern touches like D2 and ergonomic handle geometry. Jeff Lindsay started off as a bike builder - which shows in his beautiful TIG brazed handle connections…… I’m unfortunately not a bike builder and thus have resorted to more familiar stainless welded connections. While this is maybe a bit less aesthetically impressive than a tight bare bronze TIG weld, it does offer a strong bond similar in style and technique to what you see in CD, Putsch, Novotny, or Gaio Arturo cutting tools - a tired and true transition between steels with a bit of personality.

My shears feature a thick, hand carved, 3/16” vacuum hardened D2 stock with a Rockwell C of about 60, triple tempered, ergonomic handle spacing, old French style handles (later appropriated by early Putsch and Fennek), welded handle connection and a proprietary fulcrum which features a Stainless bolt and stainless split lock washer, stainless nylock nut and two Oilite oil impregnated bronze thrust bearings - all for easily customizable tension.

These high quality and highly functional tools are hand made one at a time per order in Pawtucket, Rhode Island. Each tool shows clean and visible signs of being made by hand and each is a unique object.

Tools are made per order and are selling fast, please allow some lead time for tools to be made and shipped.

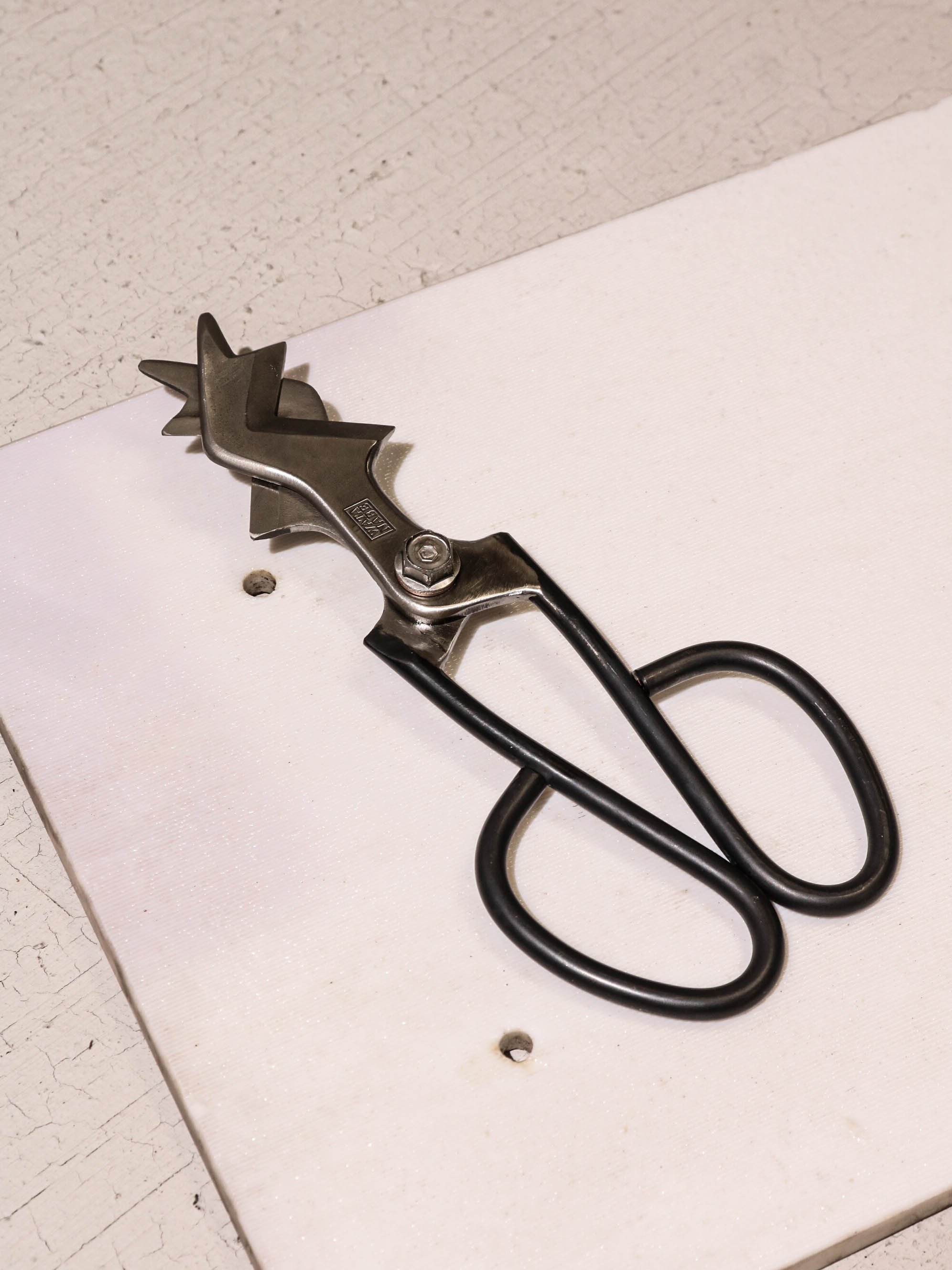

Back in 1871, hermann putsch started a company in the food processing industry with his beet slicing machine. It was several deacdes of innovation, building of mold blowing, and hot glass press forming equipment the 40’s, the establishment of Putsch groups in Spain in 1956, Italy in 1957, and the US in 1975 - that lead the company to design and build some of the glass industry’s most beloved tools and equipment. Putsch cutting tools, jacks and tweezers are very common in the European glass scene, and coveted in the states.

Putsch medium shears were very popular on the island of Murano - whether they were made in Germany, Italy or Spain, they became quite common on Italian benches since hitting the market in the 50’s. It was this tool that Gaio Arturo made his groundbreaking iteration of which lead to a new generation of ergonomic glassblowing tools that could be wielded by hands of all sizes. Jeff Lindsay later took a pair of broken Gaios (famously brittle) and re designed them once again for the modern age - adding key innovations like a form fitting pipe grabber, thinner profile, ergonomic handles, and the use of indestructible D2 tool steel. Jeff Lindsay kicked off a real movement in the states and beyond which redefined not only the look, but also the function of glass blowing cutting tools. He taught us what was possible. Maruko, NRD, Jim Moore, myself, and others have all taken careful notes from Jeff and have taken his blueprints into our own shops for further investigation.

My offering is a sort of alternate universe version of this tool. It’s an interpretation of this same historic tool, but one that looks more like the original while incorporating modern touches like D2 and ergonomic handle geometry. Jeff Lindsay started off as a bike builder - which shows in his beautiful TIG brazed handle connections…… I’m unfortunately not a bike builder and thus have resorted to more familiar stainless welded connections. While this is maybe a bit less aesthetically impressive than a tight bare bronze TIG weld, it does offer a strong bond similar in style and technique to what you see in CD, Putsch, Novotny, or Gaio Arturo cutting tools - a tired and true transition between steels with a bit of personality.

My shears feature a thick, hand carved, 3/16” vacuum hardened D2 stock with a Rockwell C of about 60, triple tempered, ergonomic handle spacing, old French style handles (later appropriated by early Putsch and Fennek), welded handle connection and a proprietary fulcrum which features a Stainless bolt and stainless split lock washer, stainless nylock nut and two Oilite oil impregnated bronze thrust bearings - all for easily customizable tension.

These high quality and highly functional tools are hand made one at a time per order in Pawtucket, Rhode Island. Each tool shows clean and visible signs of being made by hand and each is a unique object.

Tools are made per order and are selling fast, please allow some lead time for tools to be made and shipped.